Boxes are Extraordinary

Recycled

Made predominantly from trees, a renewable resource, corrugated packaging is the most recycled packaging material.

Corrugated packaging is an extraordinary recycling success story. Corrugated “cardboard” is recycled more than any other packaging material in the U.S. The industry’s unwavering commitment to increasing recovery has driven these results – demonstrated in its sponsorship of educational programs reaching schools, communities, packaging professionals and buyers, and retailers. This prolonged and focused effort on recovery and reuse is one of many things that makes corrugated cardboard boxes extraordinary, and why consumers should feel good about the boxes being delivered to their doorsteps.

That’s right: Boxes might look ordinary—but they’re extraordinary when it comes to the role they play in recycling.

The Corrugated Recycles Symbol

The Corrugated Recycles symbol can be used worldwide as a cue to box users that the package can and should be recycled. There is no cost or registration process to use the symbol. Use of the symbol on corrugated packaging is strongly supported and encouraged as long as there are no national or local laws or regulations prohibiting its use.

Click here for usage guidelines and/or to request high resolution images.

Click here for information on recyclable wax alternatives.

Why Recycle?

Recycling corrugated packaging decreases solid waste disposal. Collected fiber is then reused to make new corrugated packaging, allowing for the use of less new raw material. Recycling corrugated packaging also generates revenue for the end-user. Recovered material (called “OCC” or “old corrugated containers”) is a valuable resource to paper mills and manufacturers of new corrugated packaging.

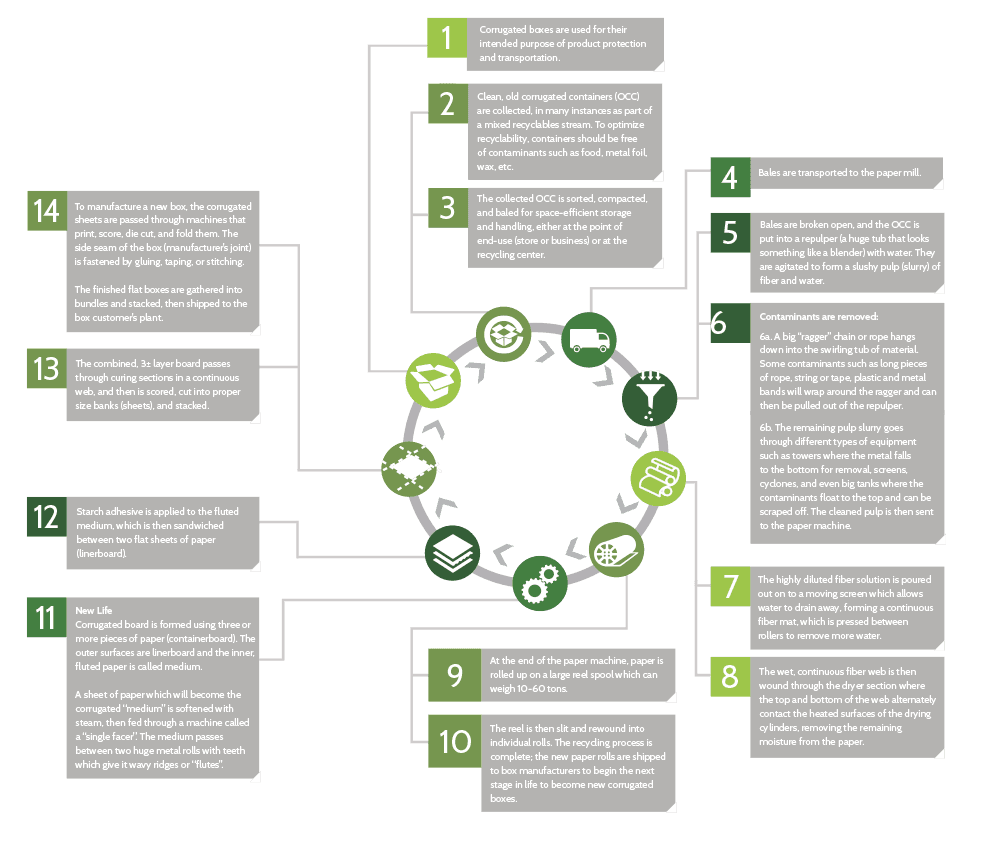

Old corrugated containers travel in a continuous loop. Most everyone contributes to this recycling success - but many people don’t understand where these boxes go or how new ones are made.

- After being used for their intended purpose they’re collected and compacted, transported to a paper mill, put into a repulper, agitated to form a slushy pulp, and cleaned of contaminants.

- That clean fiber pulp is sent to the paper machine, poured onto a moving screen, and formed into a continuous fiber mat that’s pressed between rollers to remove more water. It moves through the dryer section, is rolled onto a large spool, then slit and rewound into new paper rolls, which are shipped to box manufacturers.

- The box’s “new life” begins when the corrugated board is formed using 3 or more pieces of paper, sandwiched together with adhesive, cut into sheets, and passed through machines that make them into new boxes.

The Corrugated Cardboard Recycling Process

Businesses, retailers and consumers at home collect and return their used corrugated containers to be recycled into new ones. While almost everyone contributes to corrugated’s recycling success, fewer people may know where those boxes go from the collection point, or how they are processed to produce new corrugated material. Here’s how corrugated is recycled:

Click here for a full pdf from the Fibre Box Handbook of the corrugated recycling process.